Tag: Cheese Making

Cheese Making: Which Milks Are Used?

We love to tell you more about the cheese making process here at Shisler’s Cheese House. The more that you know about cheese, the more you can shop for your favorites and discover new delicious delights.

Today we’re going to explain the different kinds of milk used in cheese making and which cheeses you might find them in.

Sheep’s milk

Sheep’s milk has a high lactose content. This means that we rarely drink it, but it is used extensively in cheese and yogurt making. It can sometimes have a distinctive flavor, although this is often masked by the salt used to create the cheese.

Sheep’s milk cheeses include Manchego and Pecorino. Romano Pecorino is made from the milk of sheep that have grazed on specific grasses to impart flavor into the milk. If you love blue cheese, then Roquefort is made with sheep’s milk and has a great tang to it.

Goat’s milk

Goat’s milk is more regularly enjoyed on cereal or as a drink than sheep’s milk. Its qualities mean that it sometimes suitable for those who cannot have cow’s milk.

You’ll find it in simple goat’s cheese or chevre. These cheeses have a creamy texture and a distinct, complex flavor. They are great for cooking with as this flavor works well with many sweet and savory ingredients. It also melts very well, making it an excellent way to add cheesiness to dishes.

Cow’s milk

The most common of the kinds of milk used to make cheese. It has a good amount of fat and protein which makes it favorable for the cheese making process. Look out for cow’s milk cheeses that do not contain any artificial hormones.

You’ll find it in Cheddar, Swiss, and Parmesan amongst many others.

Buffalo milk

This is one of the hardest types of milk to get hold of and so it is very prized within the dairy industry. It is mostly used to make mozzarella and gives it a particularly creamy taste and texture as it has a high fat content.

More unusual milk

These are the different types of milk that you’ll usually find represented on a cheese shelf, but there are still more unusual ones being used all the time. Perhaps you might like to try reindeer or moose cheese? In some countries, cheese made from the milk of a camel is enjoyed. Donkeys, horses, and yaks have all had their milk used to make cheese to enjoy. We are also seeing a rise in non-dairy milk being used to create cheeses that are suitable for vegans or those who cannot eat dairy products. Who knows what will be next into the cheese market?

We hope you’ve enjoyed our quick tour of the different kinds of milk used in the cheese making process. Next time you pop in to fill up your cheese shelf, why not try something made form a more unusual milk and see if you can taste the difference?

Which kind of cheese is your favorite? Let us know in the comments!

Creating Homemade Coffee Cheese

Back in time, the coffee cheese was originally created from warm milk, straight from a reindeer and put in coffee to form a kind of snack. It was irresistible for someone of Northern Sweden and Tornedaling and can be just as mouthwatering to you!

Now, you may not have a reindeer or barn at hand, so you can just use raw milk or whole milk if you cannot get raw milk. Some of the time, you might not be able to get raw milk so pasteurized is fine to use, just be sure not to get UHT (Ultra-High Temp).

Recipe

What You Need

70 oz. of milk

2 oz. heavy cream

2 tsp liquid rennet

What To Do

First, pour the cream and milk into a large pan and heat to 99F.

Take the pan off the heat and stir in the rennet. Allow it to stand for 30-40 minutes or until the liquid has curdled.

Now stir gently with a slotted spoon while heating up the liquid to 99F again.

Once heated, spoon the cheese from the edges towards the center of the pan.

When the cheese is formed into a ball in the middle of the pan, heat it up to boiling point, but do not allow to boil. Take the pan off the heat to stop the whey boiling.

After taking the pan off the heat, place the cheese in either a large strainer, colander or even a cheese mold if you have one.

Be sure to press out the whey as much as possible from the cheese. Place a weight over the cheese and leave for a few hours so the remaining whey can be pressed out and the cheese dries up.

Preheat the oven to 392F and press the cheese into a greased casserole dish. Now bake the cheese into the center of the oven until it is browned.

You don’t have to bake the cheese, but it tastes a lot better when baked.

If the edges of the cheese become hard, you can just wrap it in aluminum foil afterward to soften them up.

There are many uses for the whey which is drained, for instance, using it to bake soft bread.

When the cheese is cooled, cut it into small squares, put some in a coffee cup and fill the cup with fresh coffee. Now stir it all up and eat with a spoon. The taste is so delicious, so enjoy!

If you have any left over, package it well and freeze it.

Making Something Different: Chaource Cheese

The name of this cheese alone is interesting, not to mention its unique flavor and form. You may never have heard of it, which makes it even more worth a try on firstly pronouncing (shah-oose) and then creating it!

Chaource is a mold-ripened cheese that originates from a small village in France called Chaource. It is usually made with both raw and pasteurized cow’s milk.

The rind of these cheese is similar to Camembert and has the same texture that just melts in your mouth. It can be aged for 2 weeks to 2 months and the flavor flourishes with time.

Down below is a big recipe for around 8 blocks of cheese, but you can easily half it if you so desire.

Recipe

What You Need

2 Gallons whole milk (can be pasteurized, but not ultra-pasteurized)

1/4 Tsp Mesophilic culture

1/8 Tsp Aroma Type B

1/4 Tsp Penicilium candidum

1/16 Tsp Geotrichum candidum

2 drops Animal rennet

Cheese salt

1/4 Tsp Calcium chloride

Equipment

8 Crottin molds

Thermometer

Butter muslin

Colander

Scoop or ladle

2 Bamboo ripening mats

Ripening box

Cheese wrap

What To Do

First things first, it is important that you sanitize every piece of equipment that will be used, including the ripening box.

Now dilute 1/4 tsp calcium chloride in 1/4 cup of non-chlorinated water and add this to the milk.

Heat the milk up slowly to 77F, checking the temperature with your thermometer.

Once the milk is warmed up, sprinkle all 4 cultures onto the milk and let it hydrate for around 3 minutes.

After 3 minutes, begin to stir the cultures for about 20 seconds into the milk.

Now cover the pot with a lid and let the milk ripen for around 8 hours, making sure the temperature stays at 77F for the entire period. If you are heating the pot with water, you might have to add hot water half way through the ripening to maintain the heat.

Add 2 drops of rennet to the milk and stir it in slowly for around 10 seconds.

Now cover the pot and allow it to sit for a further 8 hours, once again keeping the heat at 77F.

After the 8 hours is up, gently put the curds into a colander with a ladle, ensuring the colander is lined with butter muslin. Make sure you do not cut the curds. If you really wanted, you could skip this step and just ladle the curds directly into the molds but it can be quite difficult to get them all in.

Once in the colander, now ladle them into the 8 molds. Keep replenishing them as the whey drains from the molds.

If you would like to speed up the process of draining the whey from the molds, you can run a knife along the inside of the molds.

When the whey is getting to the bottom of the molds, empty the box. This step is important because the environment needs to be kept as dry as possible.

Let drain for around 48 hours. If the cheese seems firm enough, turn them around and put them back into the molds for 24 hours.

48 hours later, it is time to remove the cheeses from the molds and place them on wax paper or a paper towel whilst drying off the box.

Prepare your rack in the dry box.

Get each cheese and rub a thin layer of salt onto both ends of it. Be sure to wait a few minute between each end and then put each cheese into the box until they have all been salted.

Now close the lid on the box and place it in a space of 50-55F

Make sure you flip the cheeses every day and drain any whey in the bottom of the box.

The cheese will be ready to eat after 2 weeks of being in the box. If you are wanting to age them any longer, keep them in your cave with the lid ajar and make sure you flip them every day. Once you are ready to eat them, wrap them and place in the refrigerator. They’re best served at room temperature.

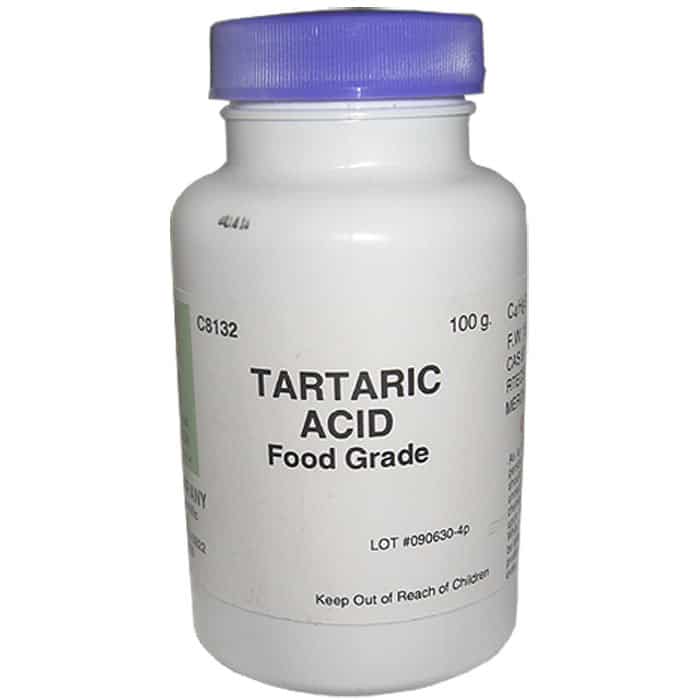

Using Tartaric Acid In Cheese Making

You can usually find tartaric acid in a lot of fruits, especially tamarind, from which tartaric acid is derived from a lot of the time. It is not only a product of cheese making though, it is also a by-product of the wine making process because it is also found in grapes.

We tend to use tartaric acid in making Mascarpone as it is an easy to make cheese and very inexpensive. It is perfect for beginners because it is consistent and works well.

It takes such a small amount of tartaric acid to make Mascarpone that when you use the full 1/4 teaspoon, there is enough to create Mascarpone 95 times from a 4-ounce packet of it. (Perfect for Tiramisu lovers!)

To make around 10-12 ounces of Mascarpone, food grade tartaric acid is used. All you have to do is add 1/4 teaspoon of tartaric acid to a quart of milk and cream or around 1/8 teaspoon for if you are using raw cream.

Recipe For Mascarpone With Tartaric Acid

What You Need

1/8-1/4 teaspoon tartaric acid

1 quart light cream or half-and-half

What To Do

1. Heat the cream to 185F in a double boiler.

2. Add the tartaric acid and stir it into the cream for several minutes. The mixture will begin to thicken into a cream of wheat consistency, with tiny flecks of curd forming. Don’t worry if the cream doesn’t seem to coagulate, just add some more of the remaining tartaric acid and stir for another 5 minutes. Just be careful not to add too much tartaric acid, or the texture will become grainy.

3. Now line a stainless-steel colander with a double layer of butter muslin. Begin to ladle the curd into the colander and drain for an hour.

4. Once that is completed, place the finished cheese in a covered container and refrigerate for up to 2 weeks. Enjoy!

Important How-To’s On Cheese Making Part Three: Bandaging Cheddar

So you’re done making your delicious cheddar cheese, the curds are pressed and you’ve removed the cheddar from the mold, it is time to bandage your cheese! Here are some useful directions that will allow for a perfectly bandaged block of cheddar, ready to age.

1. You can begin by cutting 2 circles of muslin cloth which is just slightly bigger than the top of the cheese. Now melt some lard or butter (lard is better for binding) and soak the cloth in it. This is to help the cloth to adhere to the cheese surface. Be sure to wring the cloth of excess.

2. Next, spread the cloth evenly over the surface and smooth it out from center to the edge.

3. After that, bandage the other end and repress it for about an hour at max pressure.

4. Now the side should be finished in a similar manner to the top. Put it back to press overnight.

5. Once you have removed the cheddar from the press, it will be wrapped in cloth and ready to age for around 8-24 months. To ensure this goes successfully, the cloth must be airtight and well pressed against the surface of the cheese. You should wipe away the excess lard/butter from the surface of the bandage before you place it in the cave.

6. You can now place it on a shelf in the cave at 55F and 85% humidity. Turn it once a day for the first 8-12 weeks.

7. The first natural molds will begin to show after the first 2-3 weeks. These will continue to grow and spread over time. You should begin turning only two times a week after 2-3 months of aging.

8. The mold will eventually dry off as the moisture of the cheese decreases, leaving the surface quite rustic after 8-12 months.

Cheese-Making Has Been Around For Longer Than You Might Think, Predating the Time of Jesus Christ

As we all know, Cheese has played an integral part of history, serving as sustenance through the ages for the human race since before the common era (before the time of Christ). From its infancy to the present day, although the processes have been slightly changed, adjusted and tweaked over thousands of years, the basic ideas and methodologies for cheese-making has not really changed all that much.

Cheese can come in many forms, from bricks to wheels to larger blocks. If you’d like to see a large block of cheese, stop by Shisler’s Cheese House and take a gander at our 50-pound block of Pearl Valley Swiss Cheese. One of the more unique traits to cheese is that it is one of the few foods that are more sought after for when aged, than when made fresh. Some cheese can age several months, while some can age for several years.

As we are most accustomed to cheese for its use as a means of sustenance, cheese also has served a number of purposes through the ages, many of which are entirely “unrealized” by present-day society.

If you sit down and talk to anyone involved in the meticulous process of cheese-making, while it has its variations, the most simple answer for cheese making is: warming up some fresh milk, adding a solution that would increase the acidity content that would enable the milk to become curdled. As it cools down, the extra liquid called “whey” is extracted and the resulting product is cheese. While this becoming a known fact across society and while we are aware of this process, overall, how and where did this process become the standardized way of cheese-making?

It is noted in the publication in a journal called, Nature, cheese-making process established its primitive roots some 7,000 years ago, while other sources place the first cheese-making processes around 8,000 years. Nonetheless, we are still looking thousands of years of cheese-making, and the incredible part of it all is that, for the most part, the cheese-making process has experienced very little change,aside from a number of tweaks and modifications, due in large part to ever-changing technology and machines that cut down on the process time.

Noted in the journal’s article was that the first insights leading to the belief of Neolithic cheese-making were a number of foreign vessels in which archaeologists extracted across Northern Europe over 40 years ago. What was odd with these extracted vessels was that there were holes in them, which could suggest evidence of a primitive cheese-making container.

Unfortunately, at the time, this was only one workable theory as there was no certainty behind the claim, nor a way to a prove such. As the times changes, so did the technology and with the age of mass movements in technology, this theory would finally be proven as forensics would allow scientists to discover traces of cow’s milk within these hole-riddled containers.

Cheese has been a staple for millennia as the availability and life of dairy products ultimately causing hunters to stray more away from the killing of cattle and livestock to a life more focused on dairy and dairy processes, including cheese making. While hunterss did not stray completely away from the use of cattle and livestock as sustenance, dairy and dairy process were now more favorable as hunters now had the option of now putting down their “prized” cattle for food.

Noted again in the journal, a geneticist out of University College London did tremendous research on these primitive cheese-makers only to discover that most Europeans of the Neolithic period would have been lactose intolerant, meaning, digesting the lactose sugar from milk would have been very problematic. However, during the cheese-making process, any lactose from the milk would be extracted and removed through the holes in the primitive, cheese-making containers. A chemist out of the University of Bristol in the United Kingdom discovered traces of milk buildup in pottery fragments across parts of Southwest Libya which dates back to prehistoric times.

As you can see, the evidence is quite revealing and has been scientifically proven. Cheese-making has been around for ages, dating back the some 7-8,000 years ago, essentially a world and time that has been all but forgotten of, but thanks in large part to technology, researchers, archaeologists and other scientist who dedicate their life’s work to such research, we can now begin to paint a picture of cheese-making, through the ages, even to a time before Jesus Christ, which is truly remarkable!